Description

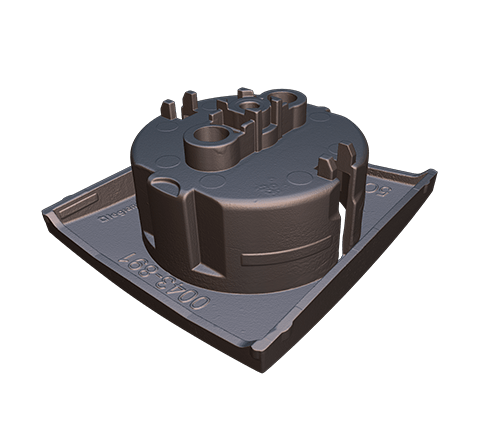

Plastic can reflect light directed at it. That’s simple yet very useful info for someone who wants to have an electrical outlet 3D scanned. This outlet was dusted before 3D scanning, which solved the issue of reconstructing the glossy parts of the surface during data processing.

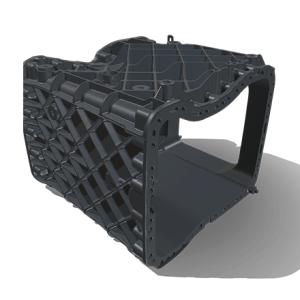

Another issue you may face once you embark upon the task of 3D scanning an outlet is this: How can you (visually speaking) get down inside all those openings and cavities? Well, some of them are accessible only via a few specific angles, which can be a bit challenging to find at first glance. You may need to run several scanning sessions in order to make sure every nook and cranny has been captured.

The good news is that you can leave this task up to Artec Micro. A fully-automated desktop 3D scanner, Micro calculates the best scanning trajectory to make sure no parts of the object’s surface are missed.