Description

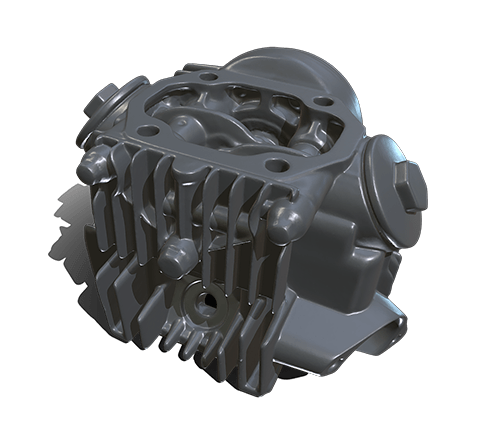

Cast from a searing-hot river of molten aluminum, this 70cc cylinder head forms the top half of the heart of a Honda C70 motorcycle engine. It encases the piston chambers, ensuring that each tiny explosion of fuel within is channeled in the right direction. A failure anywhere within or around the combustion chamber, whether it be the gasket, the inlet valve, the threaded spark plug mount, or the camshaft assembly, would be devastating.

Effectively 3D scanning such a diminutive 6″x6″x4″(15cmx15cmx10cm) powerhouse, with its diverse and sundry assemblage of parts, is a formidable challenge for a quality inspection or reverse engineering workflow. As little as a few millimeters’ variance here or there, which would be acceptable across the expanse of a chassis or bumper, is entirely unacceptable in a cylinder head.

In the past, 3D scanning mission-critical automotive components such as this could be a challenging affair. But now with the advent of Artec Studio 15’s AI-powered HD mode, capturing this little mechanical masterpiece is highly feasible with Artec Eva, and that includes even those deeper, hard-to-access sections of the cylinder head, which had previously proved elusive to even the most adept scanning attempts.

Scanned in two passes in only a morsel of minutes, using HD mode, Eva captured the cylinder head from top to bottom in 2342 sharp, high-resolution frames. Processing in Artec Studio 15 was a straightforward sequence. And a short while later the model was ready for export in a variety of formats. At that point, even without taking advantage of the host of tools and features that Artec Studio offers, the 3D model could easily be exported to Geomagic Control X for in-depth quality inspection, or over to Geomagic Design X, should reverse engineering be the next step.