Description

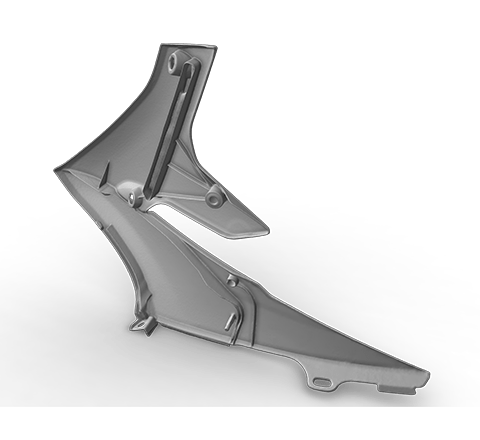

When it came time to reverse engineer a motorcycle fairing, Artec Leo was ready for the job. The original fairing would be considered as a challenging object for 3D scanning, but Leo captured the entire structure in a mere 15 minutes. Using the new, AI-powered HD Mode, all the thin edges, including the internal reinforcements, as well as the holes of various diameters, and the long, sweeping curves of the aerodynamic exterior were easily captured.

Processing the scans in Artec Studio software was simple and straightforward, taking just 20 minutes from start to finish, and requiring no actions from the user, aside from starting the Autopilot feature. As a time-saver, prior to importing the scans into the software, they had been auto-aligned directly within Leo.

Following scan processing, the 3D model was ready for export, for subsequent design modifications. At this point, the model could just as easily be used for FEA (finite element analysis) or load/stress testing simulations, whether as part of an ongoing quality process to improve an existing design, or in response to a minor or major structural failure or possible risk of the same.

This 3D model was created by Artec 3D’s Gold Certified Partner and Ambassador in Poland, 3D Master.