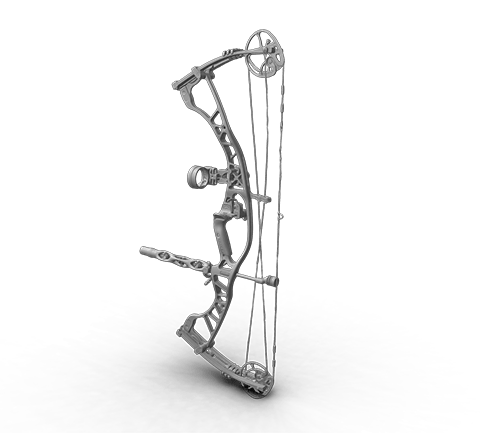

Description

This 3D model, courtesy of Paul Motley of Artec 3D Ambassador GoMeasure3D, is here to show you how you can save money on 3D scanning hardware. You probably wouldn’t think that a moderately priced Artec Eva could pick up these curved attenuated bars, a panoply of wafer-thin connecting sections, the two cams both featuring tiny apertures, not to mention all the cable work between them вАФ and that’s downright thin by definition!

This assumption could have been legitimate until the day in October 2020 when Artec Studio 15’s AI-powered HD Mode waltzed onto the stage. From that moment on, the resolution of this white-light handheld scanner, first unveiled in 2012, gets pumped to the max when scanning with HD Mode.

This means that Eva can now effectively capture a much wider range of objects than ever before. The finest of details, such as those that the bow here is abundant with, can be reconstructed in high definition with Eva, without the all-too-common gaps and levels of noise. The long and short of it is that you can digitize truly compound objects with Eva, an affordable and now, turbocharged scanner. And if you compare it with one of the non-Artec scanners that have similar specs and deliver commensurate results, you’ll see that this one is by far the best deal.

If you’re already using Eva, the great news for you is that you don’t need to buy any new hardware to scan in HD. Even if you purchased your Eva way back in 2012, all you need to do to get those crisp, hi-res 3D models is make sure you’re running Artec Studio 15. And if you’re not an Eva user yet but want to achieve the same quality results without spending a fortune, you know what to do.