Description

This 3D scanning project embodies a confluence of factors that could have complicated effective capture and reconstruction of the wild variety of shapes that needed to be captured and reconstructed in this case. Could have complicated but never really stood a chance, all thanks to the right choice of the 3D scanner to do the job – Artec Leo.

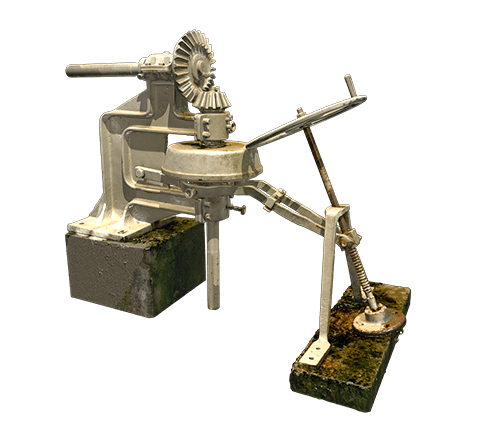

Holding this tetherless scanner with a built-in touchscreen, you can conveniently move around the object you’re scanning without worrying you might trip over the wires. No loosely hanging cords will ever get in the way when you’re scanning the upper parts of the object, which was of particular relevance for this project. And what’s also great about wireless technology is that the scanner has a battery inside and doesn’t need to be connected to an external power source, so you can scan in just about any location, not only indoors but also outdoors – that’s where this part of a mining machine was scanned. In fact, it’s an exhibit at an open-air museum in Luxembourg, the country where Artec Leos are manufactured.

Speaking of exhibits, industrial or not, when digitizing museum collections, it’s always important to ensure you can scan them the contactless way, which rules out the use of most CMM probes or 3D scanners that require dotting the object with targets to facilitate tracking. Artec Leo’s target-free scanning technology not only saves hours you’d have to spend putting stickers on the surface of an object like this section of a mining machine (and then removing them), it is also 100% safe for all types of objects as well as people, even if the laser light emitted by Leo is beaming right in their eyes.

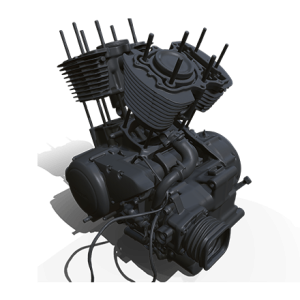

In addition to ease of use and safety, Leo stands out for its high resolution (up to 0.2 mm) and accuracy (up to 0.1 mm), which makes it a perfect tool for creating 3D models of medium-sized to large industrial objects at production facilities and design studios. This example shows how well Leo can pick up the repetitive geometry of gears and threaded stems, thin metal bars and spokes of handwheels, as well as all kinds of small fittings such as nuts, bolts, and hose clamps. Note that most surfaces are fairly reflective and scanning was done under direct sunlight, yet the object didn’t need coating with matting spray.

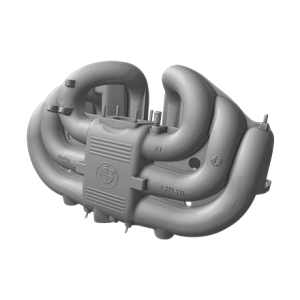

The 3D data collected by Leo can be saved to the scanner’s internal 512 GB SSD drive or micro SD cards. With Leo, you are guaranteed to have enough storage space for a large project like this one. Later on, the scans can be transferred to a PC or laptop and fused into a 3D model in Artec Studio software. Ultimately, the 3D model can be exported to a reverse engineering or CAD application. If you’re capturing heavy machinery, the 3D models can be used for various purposes, including:

- Retrofitting older machinery and equipment with 3D printed or CNC-machined parts to improve their performance, durability, energy-efficiency, etc.

- Inspecting the quality of mass-produced items.

- Assessing the wear and tear of mechanical parts.

For any of the applications listed above, you will need accurate scans that can be made quickly and easily, and that’s exactly what Artec Leo delivers.