Description

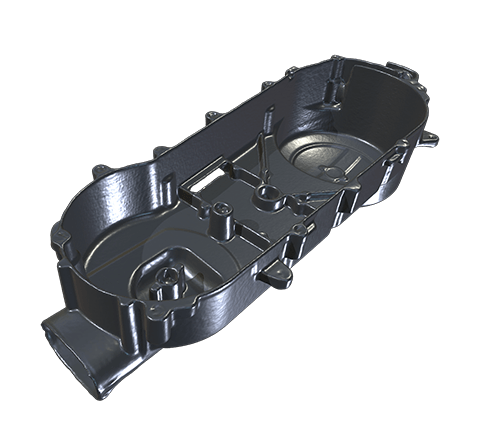

One thing to take into consideration when scanning an object with holes is that occasionally too much noise leads to the holes being blocked – which means that you can’t see through them, and they often end up not looking like the precise holes that you need in your final 3D model, which can cause problems especially in manufacturing and reverse engineering. This, however, is not the case when Leo scans with Artec Studio 15’s AI-powered HD Mode. With minimal noise, holes are not blocked and can be captured well, and seen clearly in this final result.

Looking at this motorcycle engine cover – a challenge in itself with fine details and a black surface – the increased resolution means that the edges are much sharper. This benefits not only the entire object, but also the smaller details, fine lines, and of course, the holes.

Scanned with Leo, the easiest solution becomes that much easier: Being able to scan and see in real time what you’re capturing, and the confidence that what you’re seeing translates into the 3D model after processing, too.

Have a good look around this model and have a look at the lines, the details, the form, and the fact that the 3D model represents the original object with astounding accuracy. Pay special attention to the holes. With Artec Leo, powered up with AS 15, what once seemed impossible has now become a reality – to scan not only the object but to properly capture the negative space of precisely where the holes should be.