Description

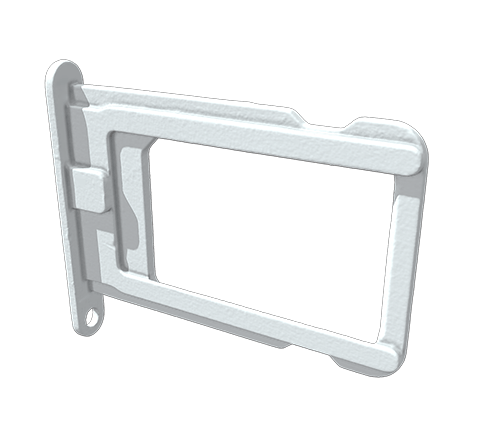

We could tell you that the Artec Micro is a high-precision industrial desktop 3D scanner that captures small objects with remarkable accuracy. A bit of a mouthful, but all true. We could also add that the Artec Micro delivers 3D scans of up to 10 microns, far beyond the human visibility threshold of 40 microns. But surely, you’ll already have heard some impressive-sounding stat from practically every scanner manufacturer. So, instead, we decided to put our desktop scanner through its paces. We scanned an ordinary, everyday object most scanners would struggle with: The SIM card tray of an iPhone 4S.

Scanning such an extremely small, incredibly thin object would be impossible for many 3D scanners. But with one click, in just ten minutes, Artec Micro was able to deliver impressive accuracy and quality. The tiny object was mounted on Micro’s scanning platform. The dual-axis rotation system automatically repositioned it, and in just a few sweeps, and at an astounding 1 million points per second, Micro’s twin cameras had captured the geometry of the tray.

It is only when you zoom in tight, however, that the scanner’s accuracy starts to become apparent. Take a close look at the ejector hole. If you are like most people вАФ no judgement here вАФ you can never find the SIM release pin that comes with your phone when you need it. So, you’ve probably tried to force the tray out with everything barring a pneumatic drill. Zoom in and you will see visible wear around the hole. For the keen-eyed, there is also a tiny scratch on the inside edge of the tray, close to the top.

Consider the many possibilities this level of precision and quality unlocks in quality control, reverse engineering, design, and a host of other use cases.