Description

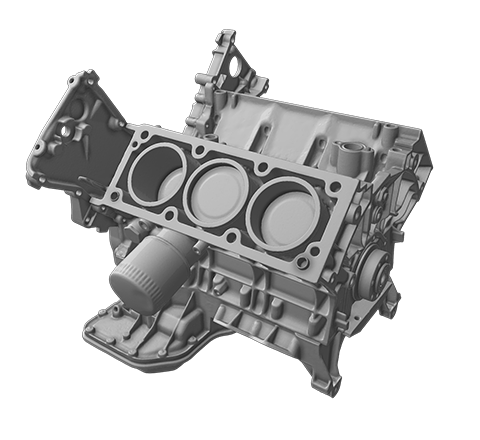

This 3D model of an engine looks like it might be a tremendously difficult job for a 3D scanner: all these intricate parts, parts both convex and hollow, a shiny surface, an abundance of thin ribs and sharp edges, and plenty of areas that are seemingly impossible to reach. Not for the new Artec Leo: now even more powerful and with guaranteed accuracy, the one-of-a-kind untethered 3D scanner nailed it in just 20 minutes. Thanks to the onboard all-powerful processor and 5.5″ HD built-in display, it is entirely possible to quickly and easily capture objects of a huge variety of sizes and complexity, as seen here.

As you explore every nook and cranny of this engine, you might be wondering how its elements have been so flawlessly rendered. This success is in no small part due to Leo’s smart surface quality indicator which highlights the areas which might need more attention or additional capturing. This model has even the most hard-to-reach areas properly captured, with no valve, crankshaft, cylinder, or even a hole left behind. In the 45 minutes needed for HD reconstruction, any noise was erased, resulting in the high resolution you see here. After 140 minutes of intuitive processing in Artec Studio, our perfectly accurate 3D model was ready.

Take a minute to explore the model up close and see all the depth of capture, which is crucial when it comes to 3D scanning complex parts in any applications, be it reverse engineering, quality inspection, or industrial design. Do rotate the model to examine the finest details and accessories in all the sections at different levels.